Anúncios

Complete Free Machinist Training Program Available Now

Start Learning Today

The manufacturing industry continues to evolve, yet skilled machinists remain in constant demand across the globe. Whether you’re looking to break into the field or enhance your existing mechanical knowledge, accessing quality training in turning and machining operations has never been more accessible. The opportunity to learn these valuable skills without financial burden opens doors for countless individuals seeking stable, well-paying careers.

Mechanical turning represents one of the foundational skills in modern manufacturing, combining precision, technical knowledge, and hands-on expertise. This comprehensive training program delivers everything from basic concepts to advanced techniques, preparing you for real-world challenges in machine shops, production facilities, and specialized manufacturing environments. 🔧

Anúncios

Why Mechanical Machining Skills Matter in Today’s Job Market

The demand for skilled machinists has remained remarkably stable even through economic fluctuations. Manufacturing facilities, aerospace companies, automotive industries, and countless other sectors desperately need professionals who can operate lathes, understand blueprints, and produce precision components.

According to recent workforce analyses, experienced machinists can command impressive salaries, with median wages significantly above national averages. More importantly, these skills provide job security that many other fields struggle to match. As automation increases, the need for skilled operators who can program, maintain, and troubleshoot complex machinery only grows stronger.

Anúncios

The beauty of machining as a career path lies in its versatility. Once you master the fundamentals of turning operations, you can work in diverse industries—from medical device manufacturing to defense contractors, from custom fabrication shops to mass production facilities. Each environment offers unique challenges and opportunities for specialization.

What This Complete Machinist Training Covers

A truly comprehensive machining course must address both theoretical foundations and practical applications. This program structures learning progressively, ensuring students build competency step by step without feeling overwhelmed by complexity.

Fundamental Concepts and Safety Protocols

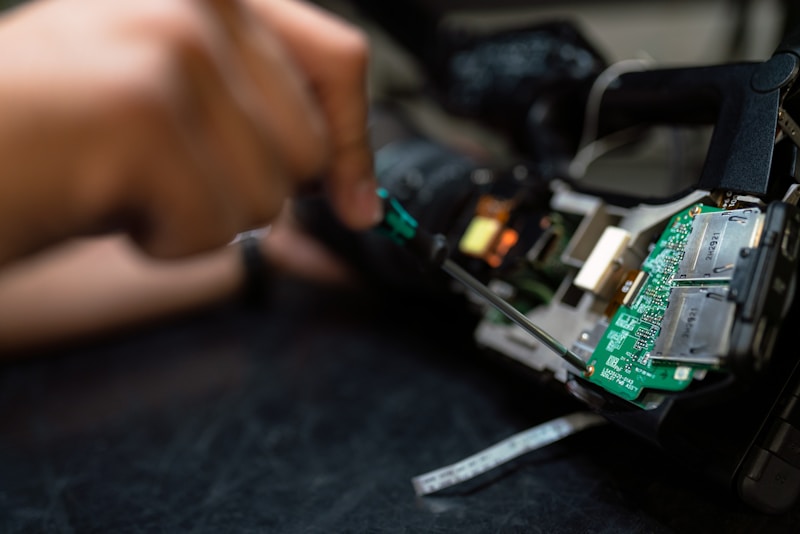

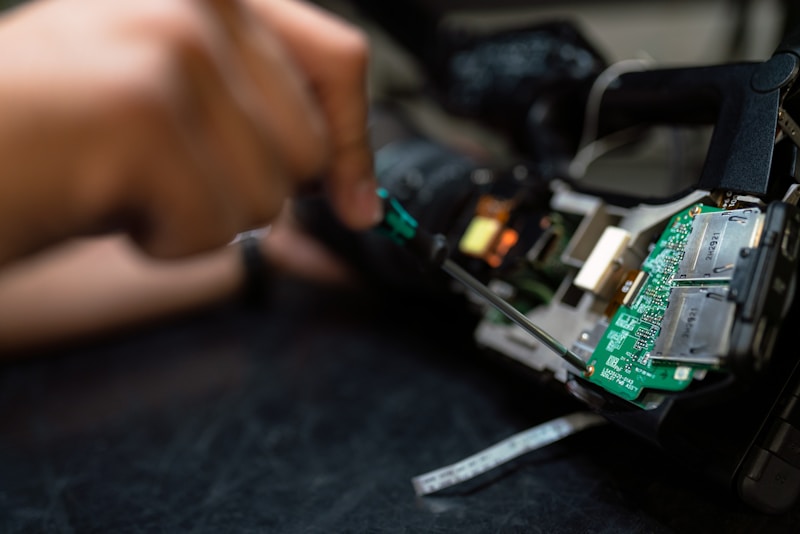

Every machinist’s journey begins with understanding the equipment, terminology, and safety procedures that protect both the operator and the work. The course introduces you to different lathe types, from manual engine lathes to CNC turning centers, explaining the purpose and capabilities of each.

Safety cannot be overstated in machining environments. Proper personal protective equipment, machine guarding, chip management, and emergency procedures form the foundation that allows you to work confidently. The training emphasizes developing safe habits from day one—habits that become automatic through proper instruction and practice. ⚠️

Reading and Interpreting Technical Drawings

Blueprint reading represents an essential skill that separates hobbyists from professionals. Understanding geometric dimensioning and tolerancing (GD&T), recognizing different view projections, and interpreting surface finish symbols enables you to transform engineering designs into physical components.

The course breaks down complex drawing standards into digestible lessons, teaching you to extract every critical dimension, tolerance, and specification needed to produce parts correctly the first time. This skill alone dramatically increases your value to employers, as it reduces errors, waste, and rework.

Material Science for Machinists

Different metals and alloys behave distinctly under cutting forces. Steel grades, aluminum alloys, brass, bronze, plastics, and exotic materials each require specific approaches regarding cutting speeds, feed rates, and tooling selection.

Understanding material properties helps you predict how a workpiece will respond to machining operations. Will it work-harden? Does it produce long, stringy chips or break into manageable segments? How does it react to heat generation during cutting? These insights directly impact your success rate and efficiency.

Mastering Lathe Operations and Techniques

The lathe stands as perhaps the most fundamental machine tool in any shop. Its ability to create cylindrical forms, threads, tapers, and complex contours makes it indispensable across manufacturing sectors.

Basic Turning Operations

Face turning, straight turning, taper turning, and shoulder turning form the building blocks of lathe work. The course teaches proper tool positioning, appropriate cutting parameters, and techniques for achieving specified surface finishes and dimensional accuracy.

You’ll learn to set up workpieces securely in three-jaw chucks, four-jaw chucks, collets, and between centers. Each workholding method has specific applications, advantages, and limitations. Selecting the right approach for each job demonstrates professional competency and directly affects productivity.

Advanced Turning Techniques

As skills progress, the training introduces grooving, parting, knurling, drilling, boring, and reaming operations—all performed on the lathe. Thread cutting receives special attention, covering both external and internal threads across various pitch standards and thread forms. 🔩

Form tools, radius cutters, and specialized tooling expand the lathe’s capabilities dramatically. Understanding when and how to use these tools enables you to produce complex geometries efficiently, reducing the need for secondary operations and setups.

Precision Measurement and Quality Control

Producing parts to specification requires accurate measurement throughout the machining process. The course covers micrometers, calipers, dial indicators, bore gauges, thread gauges, and coordinate measuring machines (CMMs).

Beyond simply using measurement tools, you’ll develop inspection strategies that verify critical dimensions at appropriate process stages. This approach prevents scrapping expensive workpieces late in production by catching errors early when corrections remain possible.

Introduction to CNC Machining Principles

While manual machining skills provide the foundation, understanding computer numerical control (CNC) technology opens additional career opportunities and significantly increases earning potential.

CNC Programming Basics

G-code and M-code form the language that controls modern CNC lathes. The course introduces these programming elements systematically, teaching you to write simple programs for turning operations before advancing to more complex routines.

You’ll understand coordinate systems, tool offsets, work offsets, and how to structure programs logically for efficiency and maintainability. Even basic CNC knowledge makes you vastly more employable, as most modern shops operate at least some computer-controlled equipment. 💻

CAD/CAM Software Fundamentals

Computer-aided design (CAD) and computer-aided manufacturing (CAM) software has revolutionized how parts move from concept to finished product. The training provides introductory exposure to these technologies, showing how engineers create 3D models and how machinists convert those models into machine instructions.

While becoming a CAD/CAM expert requires extensive additional training, understanding the workflow and basic capabilities helps you communicate effectively with engineers and programmers, making you a more valuable team member.

Tooling Selection and Optimization

Cutting tools represent one of the most critical elements affecting machining success. Proper selection impacts surface finish, dimensional accuracy, tool life, and production efficiency.

Cutting Tool Materials and Geometries

High-speed steel, carbide, ceramic, and cubic boron nitride tools each have optimal applications. The course explains the trade-offs between tool cost, performance, and longevity, teaching you to make economically sound decisions.

Tool geometry—rake angles, relief angles, nose radius, and chip breaker design—dramatically affects cutting performance. Understanding these variables enables you to select or grind tools specifically optimized for each application.

Calculating Speeds and Feeds

Running machines at appropriate speeds and feed rates balances productivity against tool life and part quality. The training teaches calculation methods for determining optimal parameters based on material type, tool material, operation type, and desired outcomes. 📊

While modern machining handbooks and mobile apps provide quick reference data, understanding the underlying principles allows you to adjust parameters intelligently when conditions vary from standard recommendations.

Problem-Solving and Troubleshooting Skills

Experienced machinists distinguish themselves through their ability to diagnose and resolve issues quickly. Chatter, poor surface finish, dimensional inaccuracy, tool breakage, and workpiece distortion all have identifiable causes and solutions.

The course develops systematic troubleshooting approaches, teaching you to observe symptoms, identify likely causes, and implement corrections methodically. This problem-solving ability becomes increasingly valuable with experience, eventually defining your professional reputation.

Career Pathways and Advancement Opportunities

Entry-level machinist positions provide solid wages and benefits, but the field offers numerous advancement paths for ambitious professionals.

Specialization Options

Many machinists develop expertise in specific industries—aerospace, medical, automotive, mold-making, or prototype development. Each specialization brings unique challenges, quality standards, and compensation levels.

Others focus on particular technologies, becoming CNC programming specialists, CAM programmers, or precision grinding experts. These specialized roles often command premium wages due to the advanced knowledge required. 🎯

Leadership and Management Roles

Experienced machinists frequently advance to lead positions, setup specialists, quality inspectors, or shop supervisors. These roles combine technical expertise with organizational and people management skills.

Some eventually transition into manufacturing engineering, process planning, or technical training roles, leveraging their shop floor experience to improve operations and develop the next generation of skilled workers.

Building Your Skills Through Continuous Practice

Like any craft, machining proficiency develops through consistent practice and deliberate skill building. The free course provides structured learning, but your growth continues through hands-on application and experimentation.

Starting with simple projects and gradually increasing complexity builds confidence and competence. Each completed part teaches lessons about material behavior, tooling performance, and process optimization that no textbook can fully convey.

Learning From Mistakes and Challenges

Every machinist occasionally scraps a part or breaks a tool. These setbacks represent valuable learning opportunities when approached with the right mindset. Analyzing what went wrong, understanding why, and implementing improvements transforms errors into expertise.

The most respected machinists openly acknowledge that decades into their careers, they still encounter new challenges and continue learning. This humility combined with curiosity drives continuous improvement and mastery.

Industry Certifications and Credentials

While hands-on skill ultimately matters most, industry-recognized certifications validate your knowledge and enhance employability. Organizations like the National Institute for Metalworking Skills (NIMS) offer standardized assessments covering various machining competencies.

Many employers value these credentials as objective evidence of capability, particularly when hiring candidates without extensive work history. The free training course prepares you for these certification exams, providing structured knowledge aligned with industry standards. 📜

The Value of Zero-Cost Professional Training

Traditional machining apprenticeships and technical school programs can cost thousands of dollars and require years of commitment before earning credentials. Access to comprehensive training without financial barriers democratizes opportunity, allowing motivated individuals to explore this career path without risk.

This approach particularly benefits career changers, young people exploring options, and those in economically disadvantaged situations. Skills acquired through dedicated study and practice hold the same value regardless of how the knowledge was obtained.

Combining Free Learning With Practical Experience

While online training provides essential theoretical foundations and conceptual understanding, machining ultimately requires hands-on practice. Many students combine free coursework with shop access through community colleges, makerspaces, or entry-level positions that provide on-the-job training.

This blended approach—structured learning complemented by practical application—often produces faster skill development than either method alone. The theoretical knowledge gives context and understanding to physical practice, while hands-on work reinforces and clarifies concepts.

Technology Trends Shaping Modern Machining

The machining field continues evolving as new technologies emerge. Staying current with industry trends ensures your skills remain relevant throughout your career.

Automation and Smart Manufacturing

Industry 4.0 concepts integrate sensors, data analytics, and networked machines to optimize production. Modern machinists increasingly work alongside collaborative robots and automated systems, requiring adaptability and technical versatility. 🤖

Rather than replacing skilled workers, these technologies typically augment human capabilities, handling repetitive tasks while machinists focus on setup, programming, troubleshooting, and quality assurance.

Advanced Materials and Processes

Aerospace and medical industries continually introduce challenging materials—titanium alloys, Inconel, carbon fiber composites—that demand specialized machining approaches. Understanding how to work with these materials creates niche opportunities with premium compensation.

Additive manufacturing (3D printing) hasn’t replaced traditional machining but has created hybrid workflows where printed components receive machined features for precision surfaces and critical dimensions. Forward-thinking machinists understand both technologies and how they complement each other.

Taking the First Step Toward Your Machining Career

Every expert machinist started exactly where you are now—curious about the field but uncertain about the path forward. The availability of comprehensive, professional-quality training at no cost removes the primary barrier that stops many people from pursuing this rewarding career.

Success in machining doesn’t require exceptional academic credentials or natural genius. It demands attention to detail, willingness to learn continuously, problem-solving mindset, and appreciation for precision craftsmanship. If those qualities resonate with you, this field offers tremendous potential for personal satisfaction and professional success. ✨

The complete course provides everything needed to build foundational competency, from safety protocols through advanced techniques. Your investment of time and focused effort translates directly into marketable skills that employers actively seek and compensate generously.

Beginning your learning journey today positions you to enter a stable, respected profession with clear advancement pathways and diverse opportunities. The manufacturing renaissance underway in many regions creates increasing demand for skilled machinists capable of producing the components that modern life depends upon.

Whether you aspire to work in cutting-edge aerospace facilities, custom motorcycle shops, precision medical device manufacturing, or any of countless other applications, the fundamentals remain consistent. Master these core skills, and you’ll possess capabilities that remain valuable throughout economic cycles and technological changes.

The decision to pursue machining training represents an investment in yourself with tangible returns. Unlike many educational paths with uncertain outcomes, skilled machinists consistently find employment, earn competitive wages, and build careers with genuine growth potential. Starting with zero financial risk makes this opportunity particularly compelling for anyone seeking meaningful work in a hands-on technical field.